5) Spanish Mountain Gold - News Release ..........

Post# of 200

October 20, 2025

Spanish Mountain Gold Initiates X-ray transmission (“XRT”) Ore Sorting Work on Gold Mineralization

https://spanishmountaingold.com/news/2025/spa...alization/

Spanish Mountain Gold Ltd. (“Spanish Mountain” or the “Company”) (TSX-V: SPA; FSE: S3Y; OTCQB: SPAUF) is pleased to announce the commencement of a particle ore sorting program with ABH Engineering Inc. and a bulk ore sorting study with OrePortal Technologies Ltd. ABH previously completed amenability tests on the mineralization from the Main deposit that indicated positive results with X-ray transmission (“XRT”) ore sorting to increase process plant mill feed grades and gold produced while targeting lower costs and improved project economics for the Spanish Mountain Gold (“SMG”) project (see January 21, 2025 news release).

OrePortal will assess if the run of mine mineralized material, prior to crushing, is suitable for ore sorting. If the assessment is successful, a material reduction of the size of the proposed mill and initial capex will be assessed.

President and CEO, Peter Mah, stated, “The amenability of the SMG project gold mineralization to XRT ore sorting is an exciting new opportunity for the project. Ore sorting is anticipated to improve the project scale and economics while derisking portions of the resource, especially lower grade feed. Preconcentrating mineralization essentially moves more gold through the process plant, which could dramatically uplift processed grades, gold production and overall project economics. This initiative is part of a multi-pronged strategy to uplift lower grade portions of the resource and improve gold production during the first ten years of the proposed PEA life of mine. We see this as an important step to complete as we advance the project towards the feasibility study and ultimately a build decision by or in 2027.”

Particle Ore Sorting Studies (ABH)

There are numerous benefits to ore sorting for the SMG project, and it is an important, potential improvement to the run of mine (“ROM”) feed grade of the process plant that could result in higher metal production, lower operating capital per tonne processed, and higher metal recoveries post processing. Particle Ore Sorting can also aid in the rejection of barren material that leads to the reduction of fine tailings, reduced materials handling charges for transportation, reduced process plant and tailings capital expenditures, and ultimately, lower impact to the local receiving environment through reduced water, reagents and overall infrastructure footprint.

The Company is proposing to undertake particle ore sorting test work that will benefit from the results from an earlier study on the Main deposit completed with ABH (see January 21, 2025 news release). The proposed work program will create multiple products and algorithms to determine the optimal sorting conditions for achieving the highest possible increase to gold recovered per tonne milled through the processing plant.

The company is proceeding with sample collection from the historical drill core at the project site. Samples for this testing will be from both Phoenix and Main deposits that provides a more direct comparison of future production results through the evaluation of the particle ore sorting performance under economic assumptions, and it shall include the development of both capital and operating expenditure estimates.

It is anticipated that this important work could find additional gold ounces that could enhance the project economics from the recent PEA (see July 3, 2025 news release). The SMG project can be scalable to meet higher production levels that with the ore sorting will match throughput for the Process Plant.

Bulk Ore Sorting (OrePortal)

The bulk ore sorting study will evaluate its amenability to the SMG project by examining several key factors that include determining the presence of ore heterogeneity. The study will also evaluate what are the preferred sensors for the ore by examining the suitability of the sensor configuration for SMG project. OrePortal employs a desktop study methodology to ascertain if further laboratory work is warranted.

The heterogeneity of the mineralization is studied through the assessment of gold distribution using the 3D block model and assay geochemistry from the recent mineral resource estimate (“MRE”) from the recent PEA (see July 3, 2025 news release). With respect to sensors, XRF and Prompt Gamma Neutron Activation Analysis (“PGNAA”) will be reviewed using suitable models of proxy elements that the sensors can detect to select a suitable model that can be used to classify ore by gold content. Examples of bulk ore sorting systems include bucket mounted XRF sensors or belt-mounted PGNAA sensors affixed to conveyor belt systems.

From the analysis, OrePortal will look to provide estimates of the capital and operating expenditures required and study the impact to the net present value of the project against the recent PEA (see July 3, 2025 news release).

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

ABH Engineering

https://www.abhengineeringinc.com/

ABOUT ABH

ABH Engineering Inc. is a mining engineering company offering geology, mining, and processing services to the mining sector. With key experience in open pit, underground, ore sorting, plant design, and optimization, our team has a passion for delivering maximum value while considering the everchanging landscape of technologies.

Our methods continue to push the boundaries on what is considered the norm for mine design. Mill feed grades can be increased while resources are expanded. Old mines can be re-opened with new, innovative equipment. Tailings ponds can be reduced or eliminated. With the proper application of technology, our team have consistently added over 40% in NPV, prevented the closing of old mines, and kept untold tonnes of CO2 out of the atmosphere, and boosted economics in an environmentally sustainable way.

What is sensor-based ore sorting?

Sensor-based ore sorting is a mineral pre-concentration technology in which particles of material are separated based on some physical or chemical property as measured or inferred by a sensor.

It is used to upgrade process feed by identifying and rejecting waste material early in the mining process which results in pre-concentration of valuable materials into a lower gross volume.

Ore sorting exploits the variability of the orebody, which in many cases is overlooked for higher volumes of feed material.

Types of ore sorting sensors

Several variables are considered when choosing an appropriate sensor for a sorting system. These include, but are not limited to, the ore mineralogy, the ore heterogeneity, the feed method, the throughput rate, and the required accuracy.

This is because different sensors have different depths of penetration, applicable size distributions, abilities to identify versus quantify ore properties and accuracies based on the target material and their specific operating parameters.

Sensing technologies that have been applied in various sensor-based ore sorting processes include:

X-ray transmission (XRT) – classifies ores according to their atomic density

X-ray fluorescence (XRF) – measures elemental abundance based on fluorescence under x-rays

Prompt Gamma Neutron Activation Analysis (PGNAA) and Pulsed Fast Thermal Neutron Activation (PFTNA) – measures elemental abundance based on gamma ray signatures from scattering events.

Colour camera – classifies industrial minerals, base- and precious-metal ores or gemstones by colour, reflection, brightness, and transparency

Laser – measures reflection, adsorption, and fluorescence of the laser light on crystal structures

Near-Infrared and Infrared (NIR/IR) – classifies and quantifies ore mineralogy according to their associated reflection, absorption, and transmission spectrum profile

Hyperspectral – classifies ores according to spectral signature across a range of visible, near infrared and short, mid, and long wave infrared bands

Magnetic Resonance (MR) – a form of radiofrequency (RF) spectroscopy that is used for quantitative measurement of target ore minerals

Laser-induced breakdown spectroscopy (LIBS) – detects elemental composition through the analysis of spectral signatures generated from high intensity laser pulses

Electromagnetic (EM) – classifies metals and ores in accordance with their conductivity and permeability.

The system and algorithms that convert the data into information used to make sorting decisions is just as critical as the sensor. Speed, accuracy, resolution, volume limitations, and detection limits of such systems are key considerations that will impact sensor selection.

Depending on where the sensing technology is positioned in the process chain and the capability of the sensor itself, additional process steps may need to be added to present the material in a specific way or divert material after it has been sensed. This includes additional equipment such as grizzlies, feeders, sizers, diverters, and conveyors.

Benefits of sensor-based ore sorting

Primary benefits obtained from ore sorting vary based on individual mine characteristics, but generally result in more metal production at a lower cost and lower environmental footprint.

Benefits may include:

Unlocked plant capacity - through earlier rejection of waste material prior to processing

Increased plant head grade - by replacing rejected waste or low grade with higher grade material in the processing plant

Reduced cost per metal unit produced - through the increase in metal produced due to higher grade feed and the reduction in costs associated with processing waste or lower grade material

Reduced tailings volume - rejecting waste from ore at an early stage allows the mass of fine final tailings to be reduced and the associated storage space

Reduced carbon emissions, water and energy consumption - rejecting waste before the processing plant and upgrading the plant feed means less tonnes of ore treated in the processing plant per ton of product. This results in reduced water usage, energy consumption and subsequent carbon emissions per metal unit produced

Increased mineable reserves - rejecting waste from run of mine ore enables mining with a lower cut-off grade and a corresponding increase in mine life

Reclaimed ore from dumps and low grade stockpiles - bulk ore sorting (or particle sorting) may enable the recovery of valuable components from waste dumps, low-grade stockpiles and marginal reserves that would otherwise be uneconomic to treat

Reduced dilution and ore loss - if applied at the mining face bulk ore sorting can reduce dilution and ore loss

Optimized capital spend - in brownfields operations capital for plant upgrades can be delayed or eliminated. For greenfield operations, plant size can be reduced, or the production rate increased

Learn more about ore sorting

To understand if ore sorting can successfully be applied to your operation, contact us to learn more and discuss how we can help you through the initial assessment process.

The technical team at ABH is uniquely positioned to deliver successful ore sorting results.

Our team can help with:

Scoping and feasibility studies

Metallurgy programs

Technology applicability reviews

Economic impact modelling

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

XRT technology (X-Ray Transmission) is expected to lower the capital expenditure (Capex) for Spanish Mountain Gold's project by potentially reducing the size of the proposed mill and initial capex. By sorting ore before it enters the mill, the company can reduce the amount of material that needs to be processed, which could allow for a smaller and less expensive processing plant.

XRT ore sorting reduces operating costs in gold production by separating valuable ore from waste rock early in the process. This process, called pre-concentration, significantly increases the grade of the material sent to the mill. This leads to lower costs in several areas, including less material needing to be mined, transported, crushed, and processed, which in turn decreases energy and water consumption, reagent use, and the amount of fine tailings requiring storage. Ultimately, it results in a higher grade of feed going to the processing plant, improving overall economic potential and reducing the environmental footprint.

Reduced plant size: XRT ore sorting can increase the grade of the mill feed, meaning a smaller mill can process the same amount of gold. A smaller mill would result in lower initial capital costs for construction.

Lower overall plant costs: Besides the initial capital, the technology could also lead to lower overall costs due to a smaller footprint and reduced materials handling.

Future assessment: Spanish Mountain Gold is currently assessing the suitability of their ore for this technology, and a successful assessment could lead to a material reduction in the size of the proposed mill and initial capex.

How XRT ore sorting increases gold grade

Sensor-based separation: XRT sensors analyze the density of rocks as they pass along a conveyor belt. They can identify and differentiate between dense, gold-bearing ore and lighter waste rock.

Targeted ejection: The system uses a high-speed air jet to eject the waste rock or lower-grade ore, while the higher-grade material is sent on to the processing plant.

Pre-concentration: This initial sorting step effectively "pre-concentrates" the ore, meaning that only the material with a higher concentration of gold is sent for further, more expensive milling and processing.

Benefits of using XRT ore sorting

Higher mill feed grade: By removing waste rock, the average grade of the ore fed into the mill increases significantly. For example, tests have shown increases of 39% for gold and 47% for silver.

Lower costs: Processing a smaller volume of higher-grade ore leads to lower processing costs for grinding, flotation, and other stages.

Reduced environmental footprint: Discarding a large portion of waste rock early reduces the amount of tailings, water usage, and energy consumption for the entire operation.

Improved project economics: The combination of higher grade, lower costs, and increased production efficiency can dramatically improve project economics, including increased IRR and faster payback periods.

Increased recovery: While not all gold is recovered in the sorting step, the material that is sorted has a much higher grade, leading to higher overall project recovery rates.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

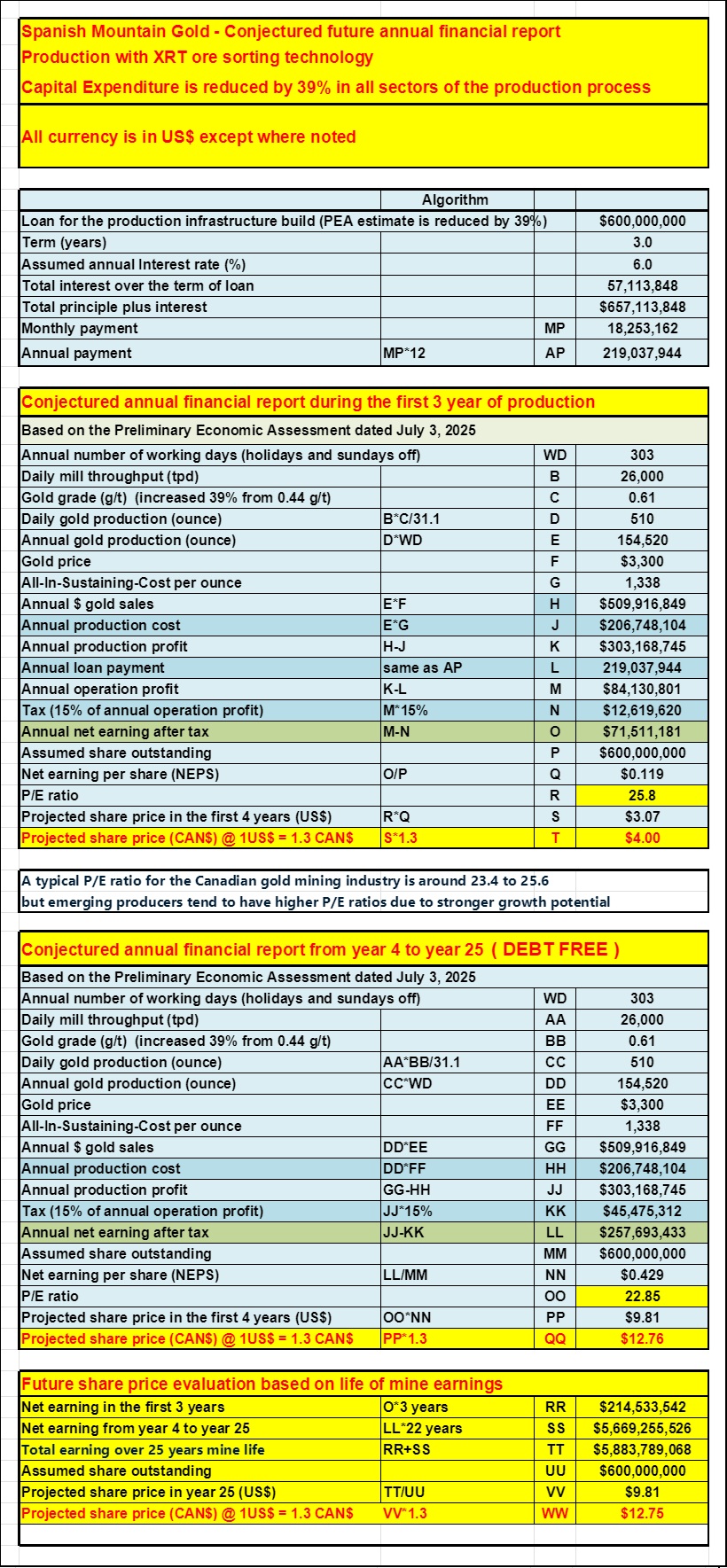

XRT ore sorting technology can reduce capital expenditure. increase gold grade and gold yield by 39%.

A conjectured future financial:

https://investorshangout.com/images/MYImages/...nology.jpg

(0)

(0) (0)

(0)