Some have scoffed at the idea of California spear-

Post# of 791

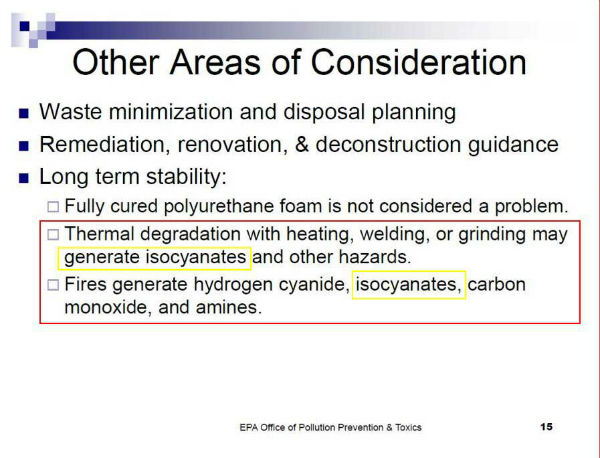

Is Hybrid Coating Technologies' (HCTI) isocyanate-free Green Polyurethane™ Solution a solution looking for a problem, or is there a real need? Did polyurethane become the new "miracle material" to follow in the footsteps of asbestos? Check out some of the links at the bottom of this post, and you may agree that it's probably a really good idea to eliminate the toxic isocyanate component from the formulation/process as soon as possible.

From 2010 through 2013, Hybrid Coating Technologies (HCTI) reported as a Development Stage Entity (FASB). Since 2014, HCTI has been commercializing the isocyanate-free product, and recently just started lining up formulation and distribution partners. Product is just now becoming available in off-the-shelf inventory.

Hybrid Coating Technologies Inc. (HCTI) is a fully compliant "SEC Reporting - Current" company trading on the OTCBB, filing audited annual reports.

A/S = 1.6B shares

O/S = 704,330,491 (November 20, 2015)

Current PPS = 0.0024 (February 26, 2016)

Market Cap (last reported O/S) = $1.69M

Current Situation - my opinion only, do your own DD, make your own decisions and trade at your own risk!

- Greatly undervalued at current price - price is depressed due to debt accumulation and dilution during Development Phase and early Commercialization/Marketing Phase; Enterprise Value (inclusive of debt) is currently ~$10M and, IMHO, should easily be several 10's of $M

- Commercializing, sub-licensing with semi-exclusivity and marketing the isocyanate-free PU product.

- Recent contracts include a $4M over 3 years minimum buy agreement with Industrial Finishes and "up to" $20M per annum agreement with Fortune 500 partner

- Servicing debt accumulated during the Development Phase and beginning of Commercialization & Marketing Phase - expect multiple accumulation opportunities with price correction plateaus (consolidation) and small pullbacks during dilutive debt-conversion share selling periods as price corrects upward in stair step fashion toward fair market value.

- Just beginning to execute contracts and accept revenue-generating orders - current active projects with 5 Fortune 500 companies and developing new relationships with others

O/S - latest "guess" is ballpark of 1B+ (will be updated again with 10-K due end of March, or more likely mid-April with "late" extension)

Market Cap - with O/S fully diluted to A/S of 1.6B, Market Cap = $3.84M

$HCTI Hybrid Coating Technologies Inc. Investor Presentation

See latest news:

http://www.otcmarkets.com/stock/HCTI/news

See latest filings:

http://www.otcmarkets.com/stock/HCTI/filings

Change begins when solutions are imminent, starting with recommendations and proposals for legislation. Environmental & health protection lobbying gains momentum when off-the-shelf solutions become available. It is reasonable to expect that the EPA, the insurance industry and many others, including special-interest groups, will take steps to avoid a repeat performance of the asbestos debacle - on any scale. With an isocyanate-free solution now becoming available off-the-shelf, it seems reasonable to expect significant change and adoption... especially one that is proven to be cost-effective while offering performance advantages.

And if you are wondering how the rest of the world might act on eliminating isocyanates from the workplace and, further, from consumer products in general, consider the following.

Many (most?) who read this will already know that polyurethane has unique properties and offers abilities that are very difficult or costly to achieve with any other solution; and that it is used in many, many products with verticals in the marketplace amounting to $xxx billions of dollars - everything from floor/surface coatings to vehicle paints/coatings to home/building insulation to many consumer products incorporating foam or cushioning materials (e.g. garments, shoes, bedding and mattress materials and much more).

This is just an excerpt from one of many sources of information related to the asbestos debacle in this country:

Quote:Here's an excerpt from another source referencing asbestos - it's not difficult to imagine PU iso-cyanates in a similar light in the near future (though likely on a smaller scale):

"Known as the miracle mineral, asbestos was used for its resiliency against chemical attack and its excellent tensile strength and superior fire-proofing characteristics. The material was used in 3,000 to 5,000 products from the early 1800s through the 1970s.

Recognizing the effects of asbestos on human health, the U.S. Public Health Service recommended guidelines on asbestos exposure as early as 1938.

Cost is a key factor. The original plan was the establishment of a $108 billion trust fund, the costs for which would be paid by corporations being sued and by insurance companies. Although expensive - $108 billion is a lot of money - corporations and insurance companies were willing to pony up in order to have a set price tag on the asbestos liability monster.

By the time the bill got out of committee, the price tag had ballooned from $108 billion to $153 billion. The insurance industry promptly dropped out, saying the cost had grown so high, it was better off with the status quo."

Quote:...especially when you - or an astute CEO or other party responsible for continuing production or installation of PU for coatings, insulation and/or fabrication of consumer goods - consider statements like the following (slides from Mary Cushman's 2011 presentation - Mary Cushman appointed to HCTI Board of Advisors August 2015):

"Besides CERCLA, asbestos is regulated as a solid waste under the Resource Conservation and Recovery Act, as a building material under the Toxic Substance Control Act, and as an airborne contaminant under the National Emission Standards for Hazardous Air Pollutants program in accordance with the Clean Air Act. The agency also limits effluent discharges for asbestos fibers in water under the Clean Water Act.

The immediate costs of the regulations to a company's bottom line should drive a practical and astute CEO to require his or her environmental department heads to find EPA-approved environmental technologies that can eliminate hazardous and regulated wastes releases once and for all. The success of this action would help alleviate the regulatory burden, increase the bottom line, solidify stockholder position and steady stock worth. "

Hybrid Appoints Retired EPA Section Chief to Board of Advisors

http://www2.worksafebc.com/i/posters/2010/ws%2010_05.html

https://www.osha.gov/SLTC/isocyanates/

http://www.cdc.gov/niosh/topics/isocyanates/

http://www.safeworkaustralia.gov.au/sites/SWA...anates.pdf

http://www.cdph.ca.gov/programs/hesis/documents/iso.pdf

http://www.ncbi.nlm.nih.gov/pmc/articles/PMC1849909/

http://www.hse.gov.uk/construction/healthrisk...anates.htm

http://www.cwa-union.org/pages/polyurethanes_..._workplace

https://www.grainger.com/content/qt-233-isocyanate

http://medicine.yale.edu/intmed/prep/worker/h...anate.aspx

http://medicine.yale.edu/intmed/prep/worker/h...ocyanates/

https://polyurethane.americanchemistry.com/He...anates.pdf

http://www.lhsfna.org/index.cfm/lifelines/dec...nsulation/

http://www.arbeidstilsynet.no/binfil/download2.php?tid=77871

http://www2.buildinggreen.com/blogs/epa-raise...insulation (at bottom, mention of HNIPUs being developed; also, good comments at bottom)

http://www.business.govt.nz/worksafe/informat...s-acop-pdf

http://www.actsafe.ca/wp-content/uploads/reso...anates.pdf

http://www.bodyshopbusiness.com/your-lungs-yo...your-life/

Hybrid Appoints Retired EPA Section Chief to Board of Advisors

San Francisco CA, August 27, 2015 -- (MARKET WIRE) – Hybrid Coating Technologies Inc.

(HCTI: OTCBB) is pleased to announce that it has appointed Mary Cushmac to its board of

advisors. Ms. Cushmac who retired from the US EPA in 2011 spent most of her career focusing

on the dangers of isocyanates in the polyurethane industry and was in charge of numerous efforts

to limit the use of isocyanates with the eventual goal of an outright ban (see full bio below). “We

are very happy to add Ms. Cushmac to our board of advisors,” said Joseph Kristul President and

CEO, “Her track record against isocyanates in the polyurethane industry and extensive

experience, brings great expertise to our team and speaks volumes as to the true potential of our

award winning technology.”

Hybrid’s patented technology is the only formulation in the world today that produces

polyurethane without the use of any isocyanates in the entire production process.

About Mary Cushmac

Mary Cushmac has more than 30 years experience at the U.S. Environmental Protection

Agency in the Design for the Environment (DfE) and the New Chemicals programs in the

Office of Pollution Prevention and Toxics. From 1997 until her retirement in 2011, she worked

in partnership with the collision repair industry and career/technical schools to develop and

promote best practices to reduce exposure to isocyanates during spray painting and related

operations. Isocyanates – key chemicals in automotive and industrial coatings – are reported to

be the leading cause of occupational asthma.

Ms. Cushmac played a major role in establishing and leading the Federal Spray Polyurethane

Foam Workgroup with participation by the Occupational Safety and Health Administration

(OSHA), the National Institute for Occupational Safety and Health (NIOSH), the Agency for

Toxic Substances Disease Registry (ATSDR) and the Consumer Product Safety Commission

(CPSC). This work group initiated dialog with the Spray Polyurethane Foam Alliance (SPFA),

the American Chemistry Council (ACC) Center for Polyurethanes Industry (CPI), and the

polyurethane foam industry to promote health and safety best practices that reduce isocyanate

exposures in spray polyurethane foamapplications.

Ms. Cushmac was also a member of the advisory panel created to advise the North Carolina

Division of Public Health and ATSDR on local communications issues related to the 2007-2010

public health study regarding isocyanate (TDI) emissions from a polyurethane plant in North

Carolina.

Ms. Cushmac joined EPA in 1980, serving as the New Chemicals Pre-notice Coordinator and

later as a section chief. She chaired the work group that developed the TSCA Pre-manufacture

Notification Rule Amendments published in 1995, and co-chaired the New Chemicals

Program's Environmental Technology Initiative that developed the 1994 Automotive

Refinishing Industry Isocyanate Profile, which outlines health and safety information on

isocyanates and recommends engineering controls and protective equipment to reduce

inhalation and dermal exposures.

Ms. Cushmac co-authored a discussion of the hazards associated with isocyanate

exposures, best workplace practices, and safer alternatives in a section of the Handbook of

Green Chemistry, Green Processes, Designing Safer Chemicals, published in 2014.

Prior to joining EPA, Ms. Cushmac worked as a research chemist in food chemistry at the

U.S. Food and Drug Administration and published several articles on analytical methods for

detecting toxins in food.

Ms. Cushmac received her undergraduate degree in chemistry at Trinity College in

Washington, D.C. and a Master's degree in organic chemistry at the Catholic University of

America in Washington,D.C. She is a member of the American Chemical Society.

CAUTIONARY DISCLOSURE ABOUT FORWARD-LOOKING STATEMENTS

This release contains "forward-looking statements" within the meaning of Section 27A of the

Securities Act of 1933, as amended, and Section 21E the Securities Exchange Act of 1934, as

amended and such forward-looking statements are made pursuant to the safe harbor provisions of

the Private Securities Litigation Reform Act of 1995. Statements in this news release other than

statements of historical fact are "forward-looking statements" that are based on current

expectations and assumptions. Forward-looking statements involve risks and uncertainties that

could cause actual results to differ materially from those expressed or implied by the statements,

including, but not limited to, the following: the ability of Hybrid Coating Technologies Inc. to

provide for its obligations, to provide working capital needs from operating revenues, to obtain

additional financing needed for any future acquisitions, to meet competitive challenges and

technological changes, and other risks. Hybrid Coating Technologies Inc undertakes no duty to

update any forward-looking statement(s) and/or to confirm the statement(s) to actual results or

changes in Hybrid Coating Technologies Inc. expectations.

About Hybrid Coating Technologies

Hybrid Coating Technologies (HCT) is a San Francisco-based innovator focused on improving

the quality and safety of foams, coatings, and adhesives for industrial and commercial customers

around the world. We are the exclusive licensee of Green Polyurethane™ foam, coatings, and

adhesives – the world’s first-ever patent protected polyurethane-based foam, coatings, and

adhesive products that eliminate toxic isocyanates from the entire production process (licensed

by Nanotech Industries, Inc.) and the 2015 recipient of the Presidential Green Chemistry Award .

The Problem of Conventional Foams/Coatings/Paint and Isocyanates

Conventional polyurethane (PU) paint and coatings have many disadvantages: they are porous,

permeable and maintain poor hydrolytic stability. This makes the material highly vulnerable to

environmental degradation and ultimately leads to their chemical decomposition, especially

when in contact with water. Conventional PU foams such as spray foam insulation are applied

via a spraying mechanism that sends toxic isocyanates in the air – exposing workers to the

dangers of toxic isocyanates. Strict and costly health & safety measures have to be implemented

in the manufacture and application of conventional polyurethane due to the toxicity of

isocyanates. This is why regulatory bodies around the world are now looking toward phasing out

the use of isocyanates.

The Green Polyurethane™ Solution

Green Polyurethane™ (also referred to as “HNIPU” - hybrid non-isocyanate polyurethane) is a

“hybrid” material that combines the high chemical resistance properties of epoxy and advanced

durability and wear resistance properties of polyurethane, making it the perfect coating

application for sanitary, high traffic and corrosive surface areas. As a hybrid material with

superior properties, Green Polyurethane ™ can be applied in one or two coatings, providing a

welcome cost-saving substitute to currently used multi-layered coating applications. Its safety

features allow it to be applied without the interruption of business due to public exposure,

creating an additional 30-60% savings on application costs for customers. As a foam, Green

Polyurethane™ provides high R values up to 6.0, energy savings up to 30% and improved tensile

strength over conventional foam without using dangerous isocyanates.

Recent Anti-Isocyanate Regulatory Pressure

US EPA MDI Action Plan: The US EPA (Environmental Protection Agency) is taking

progressive action to regulate and potentially ban isocyanates and has mentioned Hybrid’s

technology as an alternative to toxic polyurethane in its MDI Action Plan against isocyanates

(see page 4 Figovsky and Shapovalov)

http://www.epa.gov/oppt/existingchemicals/pub...ns/mdi.pdf

OSHA National Emphasis Program: On June 25, 2013 the Occupational Safety and Health

Administration (OSHA), a division of the US Department of Labor, initiated a National

Emphasis Program to protect workers from the serious health effects from occupational exposure

to isocyanates. Isocyanates are found in polyurethane based products. According to OSHA,

"Workers exposed to isocyanates can suffer debilitating health problems for months or even

years after exposure which could result in death."

California’s Department of Toxic Substances Control (DTSC) on March 13, 2014 selected

isocyanates and two others substances from a list of 1,100 toxic components that it will focus on

with the goal of potentially banning them altogether within the next two years. The

announcement is part of a bigger effort to educate consumers and manufacturers about product

safety under the Green-Chemistry Law, which went into effect in California last year. Under the

law, the agency has jurisdiction to ban these products altogether after following proper protocol.

That process includes workshops, a public comment period and requiring manufacturers that

want to sell these products in California to determine whether it would be feasible to use

safer ingredients.

The US EPA on January 8, 2015 announced that it was taking action to protect consumers from

new uses and imports of harmful isocyanates in polyurethane. The EPA’s proposed action, a

Significant New Use Rule (SNUR) under the Toxic Substances Control Act (TSCA), would

require manufacturers (including importers) to notify the EPA at least 90 days before starting or

resuming new uses of isocyanates in polyurethane based consumer products. The EPA would

then have the opportunity to evaluate the intended use of and if necessary, to take action to

prohibit or limit all products containing over one tenth of one percent of the chemical including

imported products that make their way into the United States

Public and Media Relations:

LCG

Vanessa Luna

702-761-6967

(2)

(2) (0)

(0)