EOS M290 with PrintRite3D http://jjsigmalabsblog

Post# of 382

http://jjsigmalabsblog.blogspot.com/

This article discusses laser 3D printers as the performance of the quality assurance system, PrintRite3D, will be presented at Sigma Lab's open house and Additive Manufacturing Consortium (AMC) Fall 2015 meeting on the EOS M290. Sigma Labs aim to advance additive manufacturing from prototyping to manufacturing in the aerospace industry.

The EOS M290 was chosen for the modification with PrintRite3D quality assurance system for its function and practicality. There are only a few manufacturers that have laser 3D printers that are capable of printing metals and they are ExOne, 3D Systems, Concept Laser, and EOS.

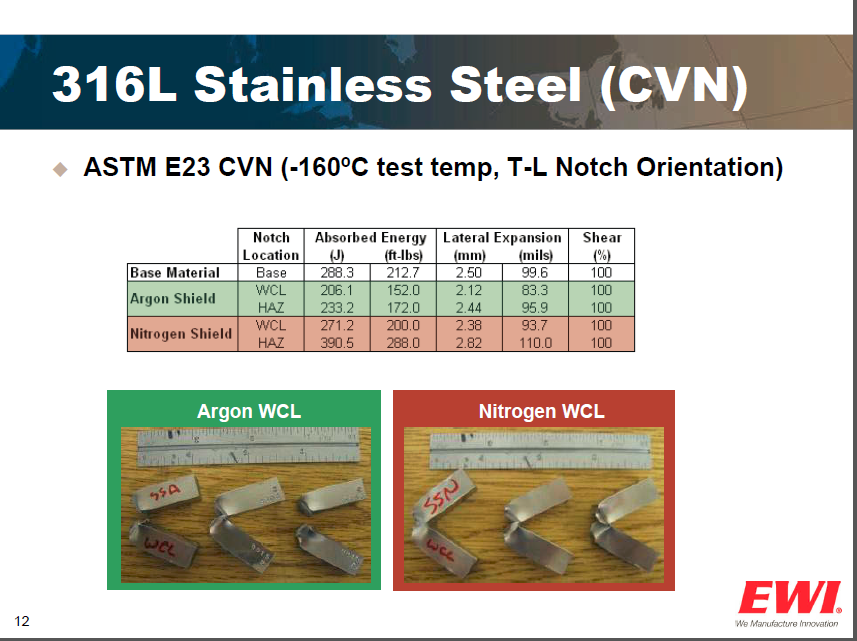

Let’s first discuss the importance of quality. There is a need for a gas shield to prevent defects. The most common gases used are nitrogen, argon, and helium. The Edison Welding Institute (EWI) has studied and compared the differences in nitrogen and argon protective gases, the occurrence of defects, and resultant mechanical properties on stainless steel, iconel 690, A508 Gr.2 steel, and iconel 718. The metals were examined for surface profile, porosity, hardness, strength, and toughness . The different outcomes between nitrogen and argon can be seen visually and measured by mechanical testing.

Thus, a shielding gas with the use of nitrogen, argon, or helium is needed to prevent defects. Let’s compare the different 3D printers.

ExOne: M-Flex

The M-Flex is not capable of 3D printing parts that will withstand the mechanical stresses in aerospace propulsion as the metal is not welded but bonded by a chemical binder.

http://www.engineering.com/3DPrinting/3DPrint...inter.aspx

3D Systems: ProX (100, 200, 300, and 400)

The ProX platform does not have a protective gas generator to create the weld environment in the 3D printer. Instead, tank(s) and services for the gas must be purchased from a 3rd party. Additive Manufacturing of New England recently purchased a ProX 300 and documented the setup of tanks and argon gas fill.

https://www.facebook.com/additivenewengland?fref=nf

Concept Laser: M1, M2 (and Multilaser), and X line (1000R and 2000R)

Similar to the ProX, a separate purchase of a nitrogen generator is needed for a supply of gas. Notice in the specifications that there are 2 connections on the 3D printer and an option to purchase a separate nitrogen (N2) gas generator.

http://www.industriallaser.com.au/pdf/M2%20Brochure.pdf

Also, the M2 has a build chamber of 250 x 250 x 280 mm. The next increase in build envelope, 630 x 400 x 500 mm, is provided by the X line 1000R which comes at a price of €1.4 million (appx. $1.51 M)

M2: 250 x 250 x 280 mm

X line 1000R: 630 x 400 x 500 mm

http://www.sme.org/MEMagazine/Article.aspx?id=73494

EOS: M290

Sigma Labs recently purchased the EOS M290 for $724,000. The M290 has a build envelope larger than Concept Laser’s M2 and the nitrogen generator is integrated .

Cost: 10K http://www.sec.gov/Archives/edgar/data/788611...68_10k.htm

M290: 250 mm x 250 mm x 325 mm

The decision for the purchase of the EOS M290 is due to overall cost effectiveness. The cost of the M290 is in the efficiency of having an integrated nitrogen generator. This is a rollover saving from the need to purchase gas tank(s) and a continuous supply of gas from a service provider.

Sigma Labs will display the efficiency of their quality assurance technology, PrintRite3D, during their open house April 14, 2015. The AMC fall meeting at their facility will be on October 28-29, 2015 and an invitation only event for EWI AMC members .

INSPECT: http://jjsigmalabsblog.blogspot.com/2015/03/s...itive.html

DEFORM: http://jjsigmalabsblog.blogspot.com/2015/03/d...sents.html

(0)

(0) (0)

(0)