PrintRite3D uses Multi-Sensor Technology for 3D Pr

Post# of 382

http://jjsigmalabsblog.blogspot.com/2014/02/p...and_7.html

PrintRite3D incorporates acoustic, thermal, and optical data for the closed-loop control of 3D printers.

Here are the specifications of PrintRite3D showing the use of acoustic, thermal, and optical monitors:

http://www.b6sigma.com/uploads/DataSheets/Pri...t_REV1.pdf

Here is an article stating how PrintRite3D uses both acoustic and optical sensors:

http://www.bizjournals.com/albuquerque/print-...l?page=all

Recall that acoustic emissions is a reliable signal that can delineate metallurgical, thermal, and mechanical properties:

http://jjsigmalabsblog.blogspot.com/2013/12/a...nergy.html

There is a 228 page study written by Hongping Gu titled, "Real-time Monitoring and Adaptive Control of CO2 Laser Beam Welding" that showed the combination of acoustic emission & optical monitoring having 98% accuracy(page 201).

https://www.google.com/url?sa=t&rct=j&...mp;cad=rja

In this study, Sigma Labs used a high speed video recorder for their IPQA demonstration for the Air Force:

http://www.b6sigma.com/uploads/media/poster.AWS-2007.pdf

http://www.b6sigma.com/uploads/media/paper.LA...e-2003.pdf

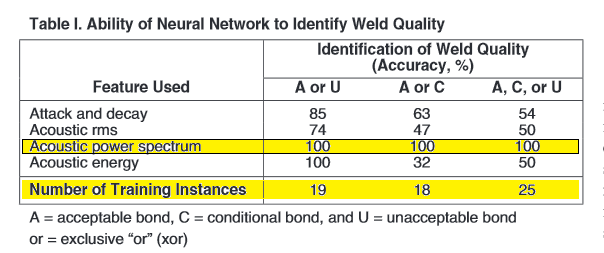

Note: Acoustic power spectrum is the ease at which signals are detected. The study showed 100% detection ability in 62 sample runs .

PrintRite3D is a complete system that incorporates acoustic, thermal, and high resolution optical sensors for quality assurance. The AM process has no system to monitor the manufacturing process and correct 3D printers. By ensuring the printing process, the need for timely post-process inspection will be amortized by Sigma Lab's IPQA technology.

|

| B6 Sigma is a whole-owned subsidiary of Sigma Labs, Inc. |

(0)

(0) (0)

(0)