Equipment and Process:

The Waste Gasification/Thermal Oxidation Plant, Scorpex chose converts waste to ash, is a two-stage waste combustion process that converts combustible organic matter from its existing solid, sludge or liquid state into a gas under an oxygen depleted environment (also know “oxidation”). The resulting gas product is then well mixed with ambient air before being burnt off in a secondary gas-processing unit.

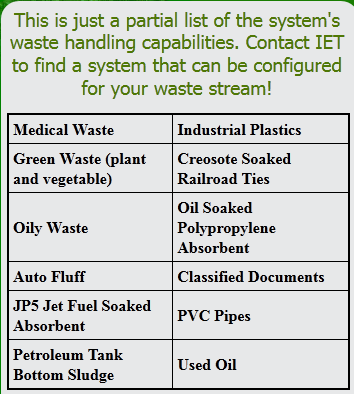

The technology converts any man made or organic waste product back to its natural state, which is inert ash or breathable air. The technology is capable of handling community solid waste content and bio-solids including medical waste, tires, plastics, wood waste, oily waste, furniture and other organic or man-made compounds found in municipal or industrial waste.

Thermal Waste Gasification:

Eliminates 99.9% of all combustible waste

Provides for 100% recycling

NO smoke or harmful Air Emissions

NO pre-sorting of trash before processing

NO odor

Moisture in the waste does not effect performance

Eliminates animals, birds, and insect scavenging in the waste

Kills all pathogens in Medical Waste

No special handling of Medical Waste

Eliminates need for landfills.

For More information visit our Partner: http://www.ietinc.net/

http://www.youtube.com/watch?v=rpbXrs0BCGQ&feature=player_embedded

The plant is comprised of three basic components: a Primary Gasification Cell, a Secondary Gas Processor, and a computerized Process Logic Controller. Combustible waste material is placed into the primary gasification cell through the load access door. In some facilities this can be done via a loading conveyor. The proposed design is to have collection vehicles dump their waste load directly into the primary oxidation cell.

The Primary Cell can be either a batch or continuous feed processor. Based on our research, batch processing provides the most efficient and cost effective strategy for the waste management solution.

Residual materials (bottles, cans, ash and misc.) need only to be removed periodically. The composition of MSW consists mainly of organic and combustible waste. Glass and metals are easily extracted in our plant design as it includes equipment that will assist in the process and cut down on labor man-hours. Ash removal is either an automated or manual process. In Automated Unloading mode, the base of the primary gasification cell contains a ductile iron furnace floor conveyor that evacuates material remaining in the base of the unit through a side access door. This dry waste material empties into a storage bin, which can be removed to another location for recycling.

Business Partners:

International Environmental Technologies, Inc. - (IET)

http://www.ietinc.net/index.html

IET is a Kentucky Corporation that has developed and patented certain technology documented in United States Patent Number 6,439,135 ("Patent") has successfully passed most restrictive environmental air emission monitoring and residual ash quality tests, as prescribed by the US Environmental Protection Agency and the European Economic Union.